Inventory is a balancing act. Too much stock? You’re tying up cash and warehouse space. Too little? You’re missing sales and frustrating customers. For decades, this was a mix of guesswork, Excel sheets, and the occasional lucky hunch. Today, artificial intelligence can improve inventory management by reducing guesswork and increasing efficiency.

Now, AI is stepping in not to replace inventory managers, but to make their lives a whole lot easier. Artificial intelligence is transforming and improving inventory management by enabling better demand forecasting, real-time tracking, and smarter decision-making.

Why Inventory Management Is Harder Than It Looks

On paper, it’s simple: keep enough product to meet demand without drowning in excess. In reality, inventory management involves juggling historical sales statistics, market trends, supplier timelines, and unpredictable customer behavior. Both consumer demand and customer demand are key drivers for inventory management, as understanding and predicting these demands is essential for maintaining optimal stock levels.

Manual processes and outdated inventory management systems often mean:

- Overstocking slow-moving items that sit for months.

- Stockouts on bestsellers right when demand peaks.

- Endless firefighting instead of strategic planning.

Failing to meet customer demand can lead to lost sales, decreased customer satisfaction, and negatively impact overall business performance.

These aren’t just annoyances. They cost money, hurt customer satisfaction, and can chip away at your brand reputation. That’s why more retailers are asking: Why use AI for inventory management in eCommerce? Leveraging data driven decision making helps businesses overcome these challenges by enabling smarter, more efficient inventory management.

How AI Is Used in Inventory Management (Without the Hype)

AI inventory management is a set of tools and algorithms that take in massive amounts of data, spot patterns, and make recommendations faster (and more accurately) than any human team could.

Here’s how it works in practice:

- Machine learning algorithms analyze years of sales history alongside market trends and external factors like seasonality or promotions.

- Predictive analytics produce accurate demand forecasts that anticipate fluctuations weeks or months ahead.

- AI-powered systems automate routine inventory tasks such as replenishment orders when stock hits pre-set thresholds, freeing up staff for more strategic work.

- Real-time inventory tracking (often via AI + IoT) keeps tabs on stock across every warehouse, store, or fulfillment center.

These AI-powered inventory management solutions optimize stock levels, improve product availability, and enable quick decision-making to adapt to market changes, ultimately enhancing customer satisfaction.

And the numbers back it up: the global AI inventory management market was worth $7.38B in 2024 and is expected to hit $9.6B in 2025, with a projected CAGR of 29.8% over the next few years.

The Key Benefits of AI for Inventory Management in eCommerce

Adopting AI inventory management software isn’t about adding another dashboard to your tech stack. It’s about creating measurable, sustained improvements in how you manage inventory, forecast demand, and run your supply chain. AI inventory management solutions also contribute to overall operational efficiency by streamlining processes and integrating seamlessly with various sales channels and third-party logistics providers.

Adopting AI inventory management software isn’t about adding another dashboard to your tech stack. It’s about creating measurable, sustained improvements in how you manage inventory, forecast demand, and run your supply chain. AI inventory management solutions also contribute to overall operational efficiency by streamlining processes and integrating seamlessly with various sales channels and third-party logistics providers.

If you’re asking “what are the benefits of AI in inventory management?” or “why use AI for inventory management in e-commerce?”, here’s the answer. It combines machine learning, real-time tracking, and predictive analytics into one AI-powered inventory management system that delivers tangible business results, including improving customer satisfaction by enabling more accurate demand forecasting and responsive inventory control.

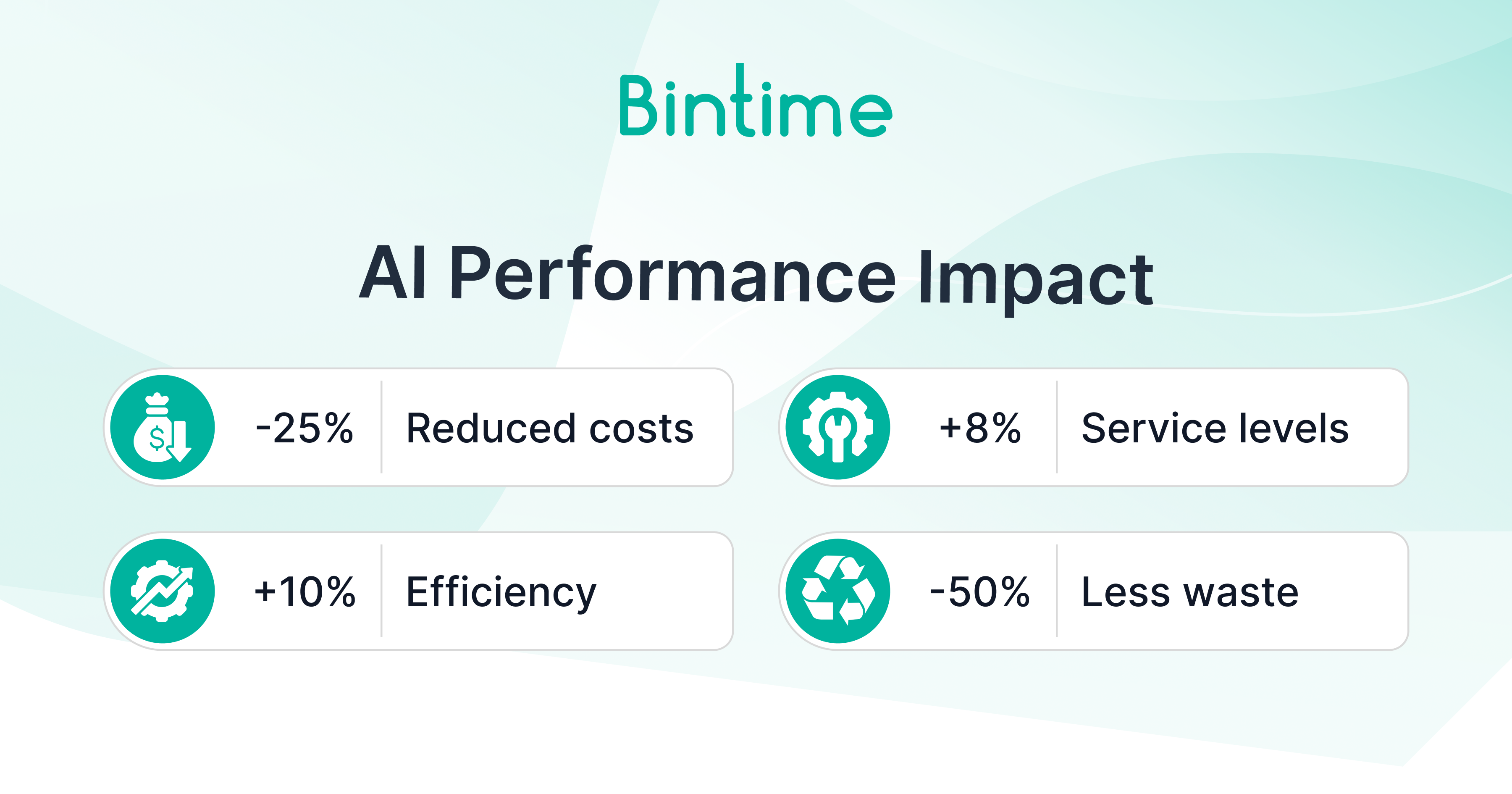

Lower inventory costs

Companies using AI for inventory management can cut inventory costs by 25% thanks to more accurate demand forecasts, automated replenishment, and better inventory optimization. Some distributors report reductions of 20–30% in inventory by combining machine learning algorithms, dynamic segmentation, and simple supply chain optimization tools. The result? Less excess inventory, fewer stockouts, and lower carrying costs.

Higher service levels

Better forecasts mean products are on the shelves when customers want them. Retailers see 5–10% service level improvements, and large distributors have improved fill rates by up to 8% by using AI-enabled supply chain control towers. These systems continuously monitor inventory levels across warehouse networks, spot potential shortages early, and recommend proactive solutions, often via generative AI chatbots that provide instant answers based on real-time inventory data.

Optimized stock levels

AI-powered inventory management systems help predict demand, maintain safety stock, and avoid over-investing in low-demand SKUs. By analyzing historical sales data, seasonal trends, and external market factors, they can keep optimal inventory levels without the guesswork.

Waste reduction

Inventory forecasting powered by AI identifies slow-moving items before they become obsolete, reducing markdowns and waste. AI also helps optimize warehouse space, which can unlock 7–15% additional capacity in existing facilities by pinpointing spare daily capacity and simulating layout and process changes.

Operational efficiency

AI eliminates time-consuming manual checks by automating routine inventory tasks, allowing teams to focus on high-value strategy. For example, a major logistics provider used a digital twin driven by AI and machine learning to boost warehouse capacity by nearly 10% without adding new real estate. This simulation-based approach improved decision-making by modeling the impact of changes in labor, assets, and material flows hour by hour.

Reduced logistics and procurement spend

AI in inventory management also optimizes the supply chain beyond stock levels, cutting logistics costs by 5–20% and procurement spend by 5–15% by improving supplier performance tracking, order consolidation, and delivery routing.

Frontline workforce optimization

Advanced analytics help businesses understand the factors influencing workforce performance, enabling targeted retention and training strategies. For example, analyzing over five million data points from driver interviews allowed one distributor to identify at-risk employee clusters and implement initiatives that improved retention, translating into a 4% EBITDA gain.

AI Inventory Management in Action. A Quick Case Example

Consider a fast-fashion apparel retailer that struggled with unpredictable demand surges and lulls. In previous seasons, this retailer often overstocked certain items (like jackets that ended up sitting in warehouses) while selling out unexpectedly of others (like trendy sneakers that vanished in weeks). These imbalances led to high holding costs for unsold stock and missed sales opportunities on popular items.

After implementing an AI-driven inventory management system:

- Data-Driven Forecasting: The AI platform was able to analyze historical sales data, along with external factors (e.g. seasonal weather trends and marketing events), to better predict demand. Instead of guessing, the retailer now had precise forecasts for each product, region, and even season.

- Proactive Reordering: The system identified an upcoming spike in sneaker demand by detecting social media buzz around a planned influencer campaign. In response, it automatically adjusted reorder quantities before the promotion hit, ensuring ample stock of the sneakers during the surge. This proactive move prevented the stockouts that would have occurred previously when an influencer drove sudden interest.

- Overstock Prevention: At the same time, the AI flagged certain jacket SKUs as slow-moving and likely to become excess stock. It recommended smaller replenishment orders for those styles, avoiding piling up unsold jackets. By predicting which items were likely to overstock, the retailer could scale back orders and discount those items earlier, rather than tying up capital in inventory that wouldn’t sell.

Results by season’s end: The retailer saw a dramatic improvement in inventory efficiency. They cut down excess inventory in half, translating to substantial savings in storage and markdown costs. In fact, one implementation of AI forecasting for a fashion chain showed overstock reduced by half, which for a company of that size meant saving hundreds of thousands of dollars in carrying costs. At the same time, stockouts of hot sellers plummeted: product availability rose so much that sales got a 10–25% boost simply because more customers found their favorite items in stock. Importantly, shopper satisfaction improved as well: customers weren’t disappointed by empty shelves (or “out of stock” messages) for those popular sneakers, which strengthened the retailer’s reputation and repeat business. These improvements were achieved through data-driven decision making, as the retailer relied on insights from AI analysis to guide inventory and restocking strategies.

Overall, this real-world example shows how AI inventory management can balance stock levels in the fast-paced retail environment. The retailer avoided costly overstock situations and lost sales, instead maintaining lean inventory and responsive restocking. By leveraging AI to anticipate demand swings (even those driven by influencers or sudden trends) and optimize orders, the company not only saved money on excess inventory but also kept its bestsellers available: a win-win for profitability and customer experience.

Sources: Companies that have adopted AI-driven demand forecasting (like one global fast-fashion chain) report up to 50% less overstock and double-digit sales increases due to fewer stockouts. AI systems achieve this by analyzing historical data plus real-time signals (weather, events, social media), enabling retailers to predict trends and adjust inventory in advance. As seen with H&M’s AI initiatives, this approach ensures high-demand items are available when customers want them while minimizing unsold stock, boosting both sales and customer satisfaction.

Tools and Systems Worth Considering

AI inventory management tools in 2025 have moved far beyond simple stock tracking. They now combine machine learning, predictive analytics, real-time data processing, and automation to optimize stock levels, improve demand forecasting, automate replenishment, and enhance overall supply chain visibility.

When evaluating AI-powered inventory management platforms, look for these core capabilities:

- Integration with existing systems (ERP, POS, eCommerce platforms).

- Real-time inventory tracking across multiple locations.

- Inventory forecasting that factors in promotions, seasonality, supply chain performance, and market trends.

- Supplier performance analytics to make smarter sourcing decisions.

- Scalability, whether you manage 1,000 SKUs or 100,000.

Some platforms offer free AI inventory management features, but paid systems often provide deeper insights and automation.

Some solutions even offer free AI inventory management features, though paid systems typically provide deeper insights, richer analytics, and more powerful automation.

Below are some of the leading AI inventory management systems in 2025 and what makes them stand out:

Logility Digital Supply Chain Platform

- Uses machine learning for demand sensing, inventory optimization, and supply planning.

- Achieves a 10–15% reduction in inventory costs and a 5–10% improvement in service levels.

- Key features: demand forecasting, supply plan optimization, real-time analytics.

o9 Solutions Digital Brain

- Combines a graph-based enterprise knowledge graph with digital twin technology to simulate and optimize supply chains.

- AI-driven planning for demand prediction, automated replenishment, and disruption forecasting.

- Delivers real-time insights for faster, better decision-making.

ClickUp

- AI-powered collaborative inventory management platform.

- Automates repetitive tasks like order scheduling and replenishment.

- Features an AI assistant (ClickUp Brain) to analyze workflows and identify efficiency gains.

Zoho Inventory

- Multi-warehouse and multi-channel inventory management for small to medium-sized businesses.

- AI-driven demand forecasting, real-time inventory tracking, and automation of purchase orders.

Freshworks

- Cloud-based AI tool for asset and inventory management.

- Simplifies procurement, automates replenishment, and offers mobile management.

- Known for its customer-focused inventory solutions.

Blue Yonder

- Uses AI and machine learning for dynamic inventory allocation.

- Offers scenario planning and real-time stock monitoring.

- Focused on maximizing ROI and customer experience.

GreyOrange

- Merges AI with robotics for warehouse automation.

- Ideal for omnichannel fulfillment and high-volume retail operations.

- Improves picking efficiency and warehouse throughput.

C3 AI Inventory Optimization

- Generates dynamic reorder recommendations.

- Balances service level goals with waste reduction.

- Focused on optimizing inventory to minimize carrying costs.

Netstock AI

- Provides AI-driven insights for strategic inventory planning.

- Simplifies data interpretation for smarter, faster decisions.

Peak’s Inventory AI

- AI-powered software focused on inventory optimization and stock management.

- Helps maintain optimal inventory levels while reducing both overstock and stockouts.

Key Features to Look For in AI Inventory Management Systems

- Demand forecasting: Analyze historical sales, market trends, seasonality, and external factors to predict future demand with high accuracy.

- Real-time inventory tracking: Monitor stock levels instantly across all locations to reduce errors and avoid stockouts.

- Automated replenishment: Use predictive analytics to auto-generate purchase orders at the right time.

- Integrated analytics: Gain insights into customer behavior, supplier performance, and inventory turnover to improve planning.

- Scalability and customization: Adaptable to different industries, business sizes, and operational complexity.

- Multi-channel & multi-warehouse support: Manage inventory across different sales channels and warehouses without friction.

- Digital twins & simulation: Use virtual supply chain models to predict disruptions, test scenarios, and optimize inventory dynamically.

The Role of AI + IoT in Modern Inventory Systems

How AI and IoT is used in inventory management has changed the game for real-time visibility and control. While AI handles the heavy lifting of predicting demand and optimizing stock, IoT devices provide the raw, continuous data that makes those predictions accurate.

Connected devices like smart shelves, RFID tags, and warehouse sensors feed live information into AI-based inventory management systems. This allows:

- Smart shelves to detect when product levels drop and trigger automatic replenishment orders.

- RFID and barcode sensors to track the exact location of items within a warehouse or across multiple facilities.

- Environmental sensors to monitor conditions like temperature or humidity for sensitive goods, alerting staff before spoilage occurs.

When AI models receive constant, accurate input from IoT devices, they can continuously monitor inventory levels, detect anomalies instantly, and adjust forecasts in near real time. The result is an agile, data-driven supply chain that minimizes stockouts, reduces overstock, and improves decision-making across the board.

Generative AI and the Future of Inventory Management

While predictive analytics has been the workhorse of inventory optimization for years, generative AI inventory management is pushing the possibilities even further. Instead of simply forecasting based on past patterns, generative AI can create entirely new scenarios to test.

For example, it can:

- Simulate what would happen to inventory levels if a supplier delay coincides with a holiday sales surge.

- Generate alternative replenishment plans that minimize risk during sudden demand spikes.

- Model the impact of launching new SKUs on warehouse capacity and overall supply chain flow.

By using generative AI in combination with traditional forecasting, retailers and distributors can prepare for “what if” situations that were once impossible to predict and adapt their inventory strategies before problems occur. This technology also supports digital twin environments, enabling planners to test ideas virtually without disrupting live operations.

Challenges and How to Guarantee ROI with AI Inventory Solutions

While the benefits are clear, adopting inventory systems isn’t without its hurdles. Common implementation barriers include:

- Cost: Initial investment in software, hardware (for IoT), and integration can be substantial.

- Training: Staff must learn to interpret AI-driven insights and trust automated recommendations.

- Integration complexity: Aligning AI tools with existing ERP, POS, and warehouse systems can be technically demanding.

To ensure success and to build AI inventory management with guarantee, companies need a solid foundation:

- Clean, comprehensive data – AI can’t make accurate predictions without reliable historical sales data, supplier performance metrics, and real-time inventory feeds.

- Clear success metrics – Define KPIs such as reduced carrying costs, improved service levels, or fewer stockouts.

- Pilot programs – Start small, measure outcomes, and scale after proving ROI.

- Continuous monitoring – Keep refining the AI models with new data and feedback from on-the-ground teams.

Vendors that offer AI inventory management guarantee programs often tie payment or contract terms to performance improvements. While these aren’t universal, they can help de-risk the investment if the provider is confident in delivering measurable results.

Conclusion: Why AI Inventory Management Is a Must for eCommerce

For eCommerce businesses facing unpredictable demand, complex supply chains, and rising customer expectations, waiting to adopt AI for inventory management automation is no longer an option.

From real-time inventory tracking powered by AI + IoT, to generative AI scenarios that prepare you for the unexpected, modern systems go beyond stock counting: they enable smarter, faster, and more profitable decision-making.

The takeaway? Start exploring solutions now. Whether you’re a mid-sized retailer or an enterprise-level distributor, implementing AI-powered inventory management today sets the foundation for cost savings, improved service levels, and long-term competitive advantage.