Introduction: Why Smart Inventory Is the Next Frontier of eCommerce

Ever had a product “available online” — only to get that dreaded “out of stock” email? That’s not just poor logistics. It’s outdated inventory logic.

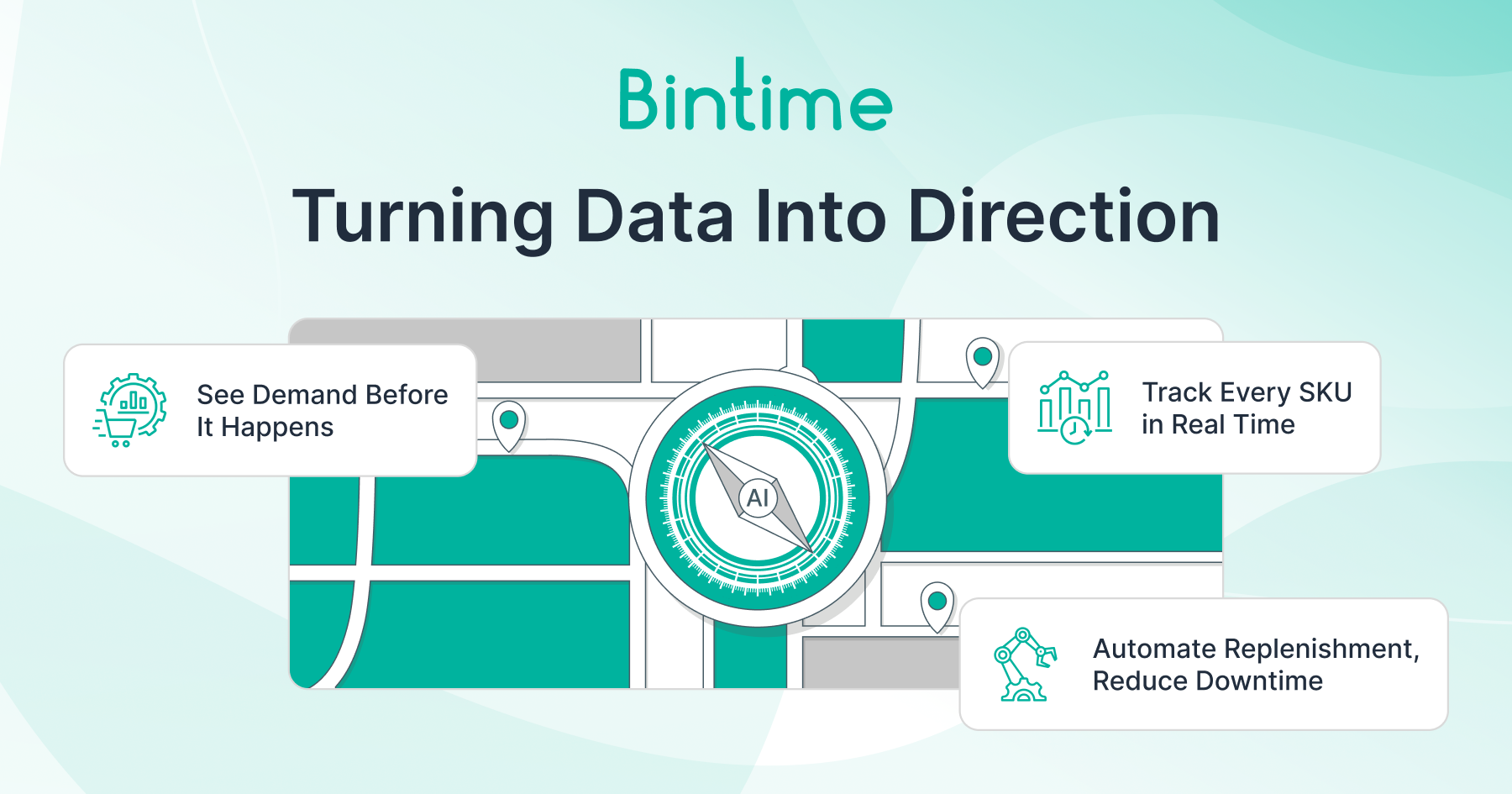

Quick answer (voice search-ready, 48 words): Smart ai inventory tools fuse sales, supplier, and customer-behavior data to run real-time inventory checks, generate hyper-accurate inventory forecasting, and automate stock control. You cut stockouts, trim dead stock, and unlock working capital — all without guessing how to do an inventory again.

Stockouts already drain almost $1 trillion in lost sales worldwide each year

hbr.org

, and manual buffers only tie up cash that could fund growth. For e-commerce operations managers like you, inventory is no longer a back-room afterthought; it’s a strategic profit lever. AI transforms every SKU into a live data node, predicting demand spikes, seasonality shifts, even viral-driven surges, then syncing replenishment across warehouses, stores, and marketplaces in seconds.

Smarter Inventory Tracking, Forecasting, and Stock Optimization

Quick answer (voice search-ready, 55 words): Modern ai inventory systems replace batch spreadsheets with real-time inventory dashboards, then layer machine-learning models that raise inventory forecasting accuracy by 20-50 percent. They automatically send the right units to the right node at the right time, so you cut holding costs, slash stockouts, and keep cash turning instead of gathering dust.

2.1 From Nightly Logs to Real-Time Line-of-Sight

Traditional logs tell you where stock was hours ago. Real-time inventory tracking tools—fed by RFID tags, IoT sensors, and cloud APIs—show where every SKU is right now, down to aisle and bin. Research shows that this live visibility is the fastest route to eliminating both stockouts and overstock penalties.

ResearchGate

2.2 Region- and SKU-Specific Demand Prediction

AI crunches web traffic, marketplace searches, weather signals, and social mentions to anticipate demand shifts before they hit your P-&-L. McKinsey finds that applying AI forecasting in supply chains trims error rates by 20–50 percent and can reduce lost-sale events up to 65 percent.

McKinsey & Company

Target’s Inventory Ledger now runs billions of micro-predictions each week, doubling coverage in two years and reallocating stock to the exact ZIP codes that need it most.

Business Insider

2.3 Beyond “How Many?”—Timing and Placement

Stock optimization isn’t just a quantity game; it’s a when and where problem. AI models create dynamic reorder points that flex with seasonality, promotions, and supply variability, then recommend node-level placement—metro-warehouse, store backroom, or micro-fulfillment center—to minimize last-mile costs and delivery times. JUSDA’s roll-out, for example, cut forecast mistakes by up to 50 percent and freed millions in working capital.

jusdaglobal.com

2.4 Autonomous Replenishment Loops

Once demand curves and holding-cost constraints are nailed, the system can trigger autonomous purchase orders, cross-dock transfers, or vendor-managed inventory calls—no spreadsheets, no late-night phone trees. The result: fewer fire-drill escalations and a supply chain that actually sleeps at night.

Spare Parts Inventory and Part Tracking Systems

3.1 Spare Parts ≠ Standard Stock

Regular merchandise churns by season or promo; spare parts spike only when assets hiccup. AI models ingest failure histories, BOM hierarchies, and manufacturer obsolescence notices to map each item’s demand cycle, dependency web, and end-of-life risk. Verusen’s algorithm, for instance, continually re-scores “critical-to-operate” parts so you can trim dead weight without gambling on uptime.

Verusen

3.2 Criticality-Based Control Plans

Traditional ABC classification stops at velocity. An AI-enabled inventory control plan layers in:

Failure probability (P-fail) from predictive-maintenance sensors

Downtime cost (C-down) per hour

Lead-time volatility (σ-LT) from supplier feeds

The system multiplies these signals into a criticality index that updates in real time and drives reorder points. Companies using ThroughPut’s spare-parts optimizer freed millions in working capital while keeping service levels above 97 %.

ThroughPut Inc.

ToolsGroup

3.3 Multi-Channel Coordination—Right Part, Right Node

Your part inventory system no longer lives in one DC. AI reconciles depot, field-van, and third-party stock, then decides whether to:

Re-position parts overnight to the region with the highest P-fail

Cross-dock from a low-criticality site to a high-criticality site

Drop-ship from a vendor to the job site when compliance rules on payment gateways are met

McKinsey notes that predictive maintenance slashes unplanned downtime by up to 50 %, proving that stocking the correct gasket in the right city is worth more than hoarding a year’s supply in the wrong one.

Case in Point: AI-Flagged Compressor Saves the Shift

A global beverage plant outfitted its chillers with vibration IoT sensors. At 02:17 AM on a Friday, the AI flagged a failing compressor bearing. The ai inventory layer checked node-level availability and saw the replacement in a nearby 3PL hub. It auto-generated a rush pick, triggered payment-gateway compliance checks, and had the part on-site by 08:00. Result: 30 % less downtime and zero lost production hours.

Real-Time Inventory Software, UI Design & Workflow

Quick answer (voice search-ready, 51 words): Modern inventory software puts real-time inventory data on role-based dashboards. AI surfaces only what matters—low-stock alerts, ETA delays, transfer picks—while auto-suggesting next steps. You get fewer clicks, faster decisions, and a workflow that keeps every SKU in view without drowning teams in noise.

4.1 Design for Focus, Not Flash

Great inventory UI design hides 90 % of the clutter. AI filters billions of signals and pushes just six “need-to-act” cards: (1) stockouts imminent, (2) late inbound, (3) fast-movers trending up, (4) slow-movers ripe for markdown, (5) payment-gateway compliance holds, (6) recall flags. Starbucks’ new AI interface, rolled out to 11 000 stores, cuts shelf-count time by a factor of eight and prompts staff only when oat milk or caramel drizzle dips below par.

Reuters

4.2 Dashboards that Speak Each Role’s Language

A logistics coordinator cares about dock congestion; a category manager wants GMROI. AI tailors widgets automatically:

Logistics view: trailer queue, put-away velocity, smart buffer levels

Merchandising view: sell-through heat map, promo cannibalization risk

Finance view: days-on-hand trend, working-capital unlocked by transfers

Walmart’s AI suite now pipes these views to 20 000 managers, recalculating optimal safety stock hourly and pushing region-based transfer recommendations that have cut store-level gaps by double digits.

Business Insider

4.3 Real-Time Visibility Down to the Bin

Legacy ERP snapshots age out within hours. Today’s platforms stream RFID, POS, and WMS events under 30 seconds, then visualize location, lot, and expiry at SKU level. A March 2025 study found that firms integrating real-time inventory feeds with AI forecasts lifted order-fill rates by 12 % while trimming excess stock 18 %.

ResearchGate

4.4 Proactive Workflow: From Alert to Action

The system doesn’t stop at “what.” It prescribes “now do this” with one-click tasks:

Auto-replenish from the DC with surplus, hitting payment-compliance rules en route.

Trigger transfer to the micro-fulfillment node nearest the demand spike.

Launch markdown campaign on aged units, with predictive-advertising hooks pre-filled.

An April 2025 field trial reported 25 % faster issue resolution when AI wrote the task list versus humans manually triaging alerts.

ijisrt.com

“If your dashboard still shows 42 columns, you’re missing the point—AI should give every user exactly three buttons: act, delay, or ignore.” — Brand Product Lead

Takeaway: Design the UI around actionable signals, personalize dashboards by role, and stream real-time SKU data into AI workflows. You’ll shrink cognitive load, accelerate response, and keep inventory exactly where—and when—it needs to be.

AI Use Cases in Inventory Strategy & Retail Sector Analysis

Quick answer (voice search-ready, 53 words): Top retailers run ai inventory platforms that auto-restock fast movers, route SKUs to the best node, time markdowns to the minute, and flag supplier delays days ahead. You gain higher in-stock rates, lower freight costs, and a supply chain that anticipates shocks instead of reacting late.

- Demand-Aware Restocking

Walmart’s “agentic AI” ingests sales, weather, local events, and macro signals to create billions of micro-forecasts each day, then pushes dynamic purchase orders to stores and DCs. Executives report double-digit cuts in shelf gaps and a working-capital reduction worth hundreds of millions.

DigitalDefynd Education

Walmart Corporate News and Information

- Geo-Intelligent Fulfillment

Amazon’s 2025 “Wellspring” initiative marries generative mapping with demand AI to pre-position SKUs within 100 miles of predicted buyers. Early pilots trimmed last-mile mileage 12 % and shaved a full day off Prime delivery promises—without adding fulfillment sites.

aboutamazon.com

- Product-Lifecycle Optimization

Fast-fashion icon Zara lets machine-learning models track sell-through velocity against style freshness. When a design hits its decay curve, the system recommends price drops or store transfers—freeing racks for new drops and cutting end-season markdown losses up to 15 %.

CTO Magazine

- Risk Mitigation via Supplier-Delay Prediction

AI engines now fuse vessel telemetry, port congestion feeds, and supplier ESG scores. Platforms like Leverage alert planners when a Tier-2 component faces delay, then simulate inventory buffers and auto-source alternates. Retailers using these tools report 20 – 30 % fewer production halts during 2025’s logistics snags.

blog.tryleverage.ai

“When your inventory tech senses storms before your suppliers do, stockouts become a choice, not a surprise.” — Brand Head of Supply Resilience

Takeaway: Shift from periodic reviews to continuous, AI-guided loops. Let demand-aware models pull product, geo algorithms place it, lifecycle optimizers time its exit, and risk engines guard the flanks. Together, they turn what used to be a cost center into a predictive advertising-fueled growth flywheel—one SKU, one second, one insight at a time.

Final Thoughts: A New Era of Inventory Intelligence

Inventory has broken out of the back room. With AI watching every SKU in real time, stock is no longer a cost you nurse—it’s a capital asset you deploy. You’ll channel working-capital into growth instead of safety buffers, hit promised ship dates with surgical accuracy, and replace “sorry, out of stock” with instant trust. The mindset flips from cutting costs to competing on availability: whoever sees demand first, ships fastest, and reallocates smartest wins.

Here’s how the shift looks at a glance:

Inventory Then vs. Now

| Aspect | Then: Manual & Reactive | Now: AI-Powered & Strategic |

| Visibility | End-of-day spreadsheets | Live, SKU-level dashboards |

| Speed | Weekly reorder cycles | Sub-minute auto-replenishment |

| Decision-Making | Gut feel & static rules | Predictive models & simulations |

| Business Impact | Cost-center firefighting | Growth engine and trust driver |

FAQ Section

Q1. What is AI-powered inventory management and how does it work?

AI inventory platforms combine machine-learning models with real-time inventory data to predict demand, automate replenishment, and flag anomalies before they become costly stock-outs.

Q2. How does AI improve inventory forecasting in retail?

Through predictive analytics, AI sifts historic sales, promotions, and external signals to deliver precision inventory forecasting, letting retailers optimize stock and slash carrying costs.

Q3. What’s the difference between traditional stock control and AI-driven inventory tracking?

Conventional stock control software relies on static reorder points; an AI inventory tracking tool learns from every transaction, constantly recalibrating thresholds and surfacing actionable insights from each inventory example.

Q4. Can AI help manage spare parts inventory more efficiently?

Absolutely. A part inventory system powered by AI classifies critical SKUs, anticipates failure rates, and recommends an inventory control plan that keeps vital spares on hand without bloating capital.

Q5. Why is real-time inventory visibility critical for modern eCommerce?

Shoppers expect accurate availability; real-time inventory tech syncs every sale instantly across channels, safeguarding customer trust and unlocking agile, data-driven inventory business decisions.