Let’s be honest – supply chains have been through the wringer. Global disruptions, unpredictable demand spikes, and an ever-growing list of customer expectations have made it nearly impossible to “just wing it” anymore. So, what’s the solution? It’s not more spreadsheets. It’s AI in supply chain – and it’s already reshaping how logistics and operations work in 2025.

From smarter forecasting to automated decision-making, AI has evolved from a buzzword to a must-have. And no, we’re not talking sci-fi robots. We’re talking real tools solving real problems in real time – as you’ll see in the AI in supply chain examples we’ll cover throughout this piece.

And this isn’t a fringe movement anymore. The global AI in supply chain market is expected to skyrocket from USD 4.5 billion in 2023 to a staggering USD 157.6 billion by 2033, growing at a CAGR of 42.7%. That’s not hype – that’s an entire industry shifting gears fast, fueled by software, analytics, and digital transformation.

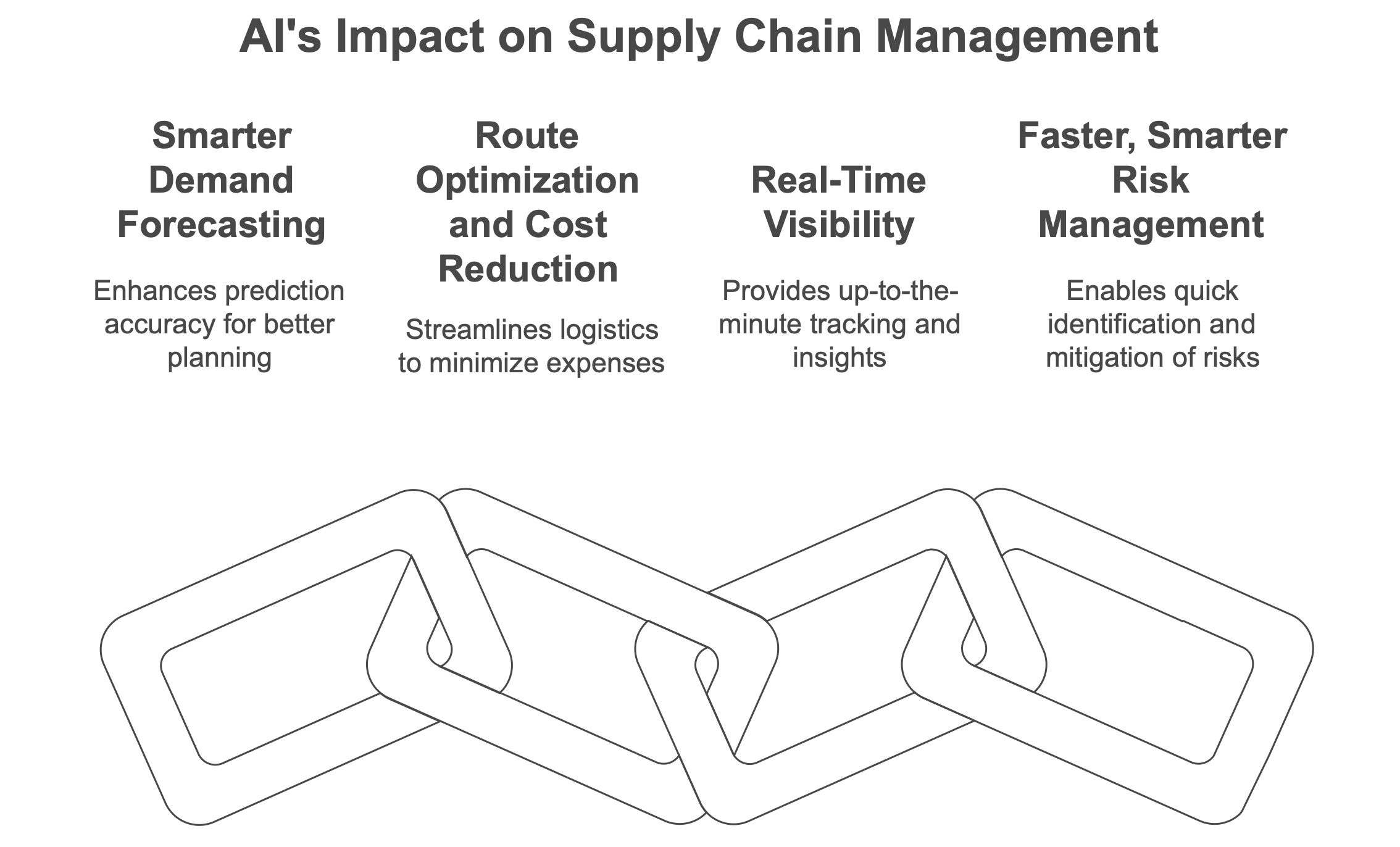

Benefits of AI in Supply Chain Management

If you’re thinking AI sounds promising but maybe a little “overhyped,” let’s break down what it actually does – and why it’s making supply chain execs sleep better at night.

#1. Smarter Demand Forecasting

AI systems are no longer just number crunchers. They learn from every SKU, season, promo, and even that one influencer post that suddenly spikes demand for lavender candles. By pulling information from sales history, market trends, and external factors like weather or geopolitical shifts, AI can forecast demand with scary accuracy.

The benefits of AI in the supply chain really shine here: fewer missed sales, tighter inventory, and a lot less guesswork.

That means fewer stockouts, less excess stock, and a better shopping experience for end customers – especially online, where poor availability leads to lost sales instantly.

#2. Route Optimization and Cost Reduction

It’s not just about getting things from A to B anymore. It’s about getting them there fast, cheap, and in a way that keeps carbon footprints in check. AI-driven route optimization adapts to real-time conditions – like traffic, fuel costs, or warehouse constraints – helping logistics teams cut costs and emissions without compromising speed.

#3. Real-Time Visibility

The days of “we think your package is somewhere in Ohio” are over. With AI, companies can track products from factory to doorstep, giving both internal teams and customers the visibility they crave. It’s not magic. It’s machine learning, sensor data, and predictive alerts working together make it easy to search inventory availability, shipment status, and warehouse data – all in real time.

#4. Faster, Smarter Risk Management

Let’s face it: delays, shortages, and disruptions aren’t going anywhere. But with AI in supply chain optimization, companies can react faster – rerouting shipments, shifting production, or sourcing alternatives automatically. It’s like having a risk radar that’s always on.

And that’s just scratching the surface of the use of AI in supply chain management – we’re talking better agility, smarter decisions, and way fewer surprises.

Key AI Technologies Transforming Supply Chains

Okay, so what’s under the hood? Not all AI is created equal. Some technologies are doing more of the heavy lifting than others.

Machine Learning: The Brain Behind the Forecast

ML is the workhorse of AI in supply chain management. It takes historical data, adds some predictive sauce, and outputs forecasts, delivery timelines, and performance metrics. It’s used to optimize stock levels, improve online fulfillment, and even refine listings and descriptions based on real-time demand signals.

Computer Vision: Eyes on the Ground

Whether it’s checking if a product is labeled correctly or scanning pallets for damage, computer vision helps teams maintain quality without relying on manual checks. Tyson Foods uses it for visual inspections, catching issues before they snowball into costly recalls.

NLP: Automating the Paper Trail

Natural Language Processing is the behind-the-scenes hero that processes documents, answers queries via chatbots, and even handles supplier emails. It doesn’t just save time – it reduces errors and keeps communications running smoothly across the board. Also pulls insights from content, such as customer service messages or product reviews, to highlight recurring supply chain issues.

Generative AI: Scenario Planning on Steroids

Want to model a worst-case logistics scenario or test the impact of a new supplier? Generative AI in the supply chain lets teams play out “what-if” scenarios before making costly moves. It’s also being used for anomaly detection – spotting weird patterns in returns or delays before humans even notice them.

This kind of gen AI in supply chain gives operations a new kind of foresight – one that’s adaptable, flexible, and surprisingly creative.

Real-World Use Cases and Examples

All this tech talk is excellent, but let’s talk about receipts. Who’s using AI in supply chain, and what are they getting out of it?

SAP: Precision Demand Planning

SAP’s AI systems help clients adjust production and distribution plans in real-time, cutting waste and responding quickly to market shifts. With predictive modeling, teams don’t just plan – they adapt on the fly.

UPS: Smart Deliveries and Dynamic Routing

UPS doesn’t just deliver boxes. It delivers them with AI-optimized routes that save millions of miles each year. Their ORION system uses historical and real-time data to dynamically adjust driver routes, saving them an estimated 100 million miles annually. That’s not a typo.

Tyson Foods: Quality Control with Computer Vision

We mentioned Tyson earlier, but it’s worth repeating. They use computer vision systems in processing plants to detect anomalies faster than human inspectors, keeping food safer and reducing waste. It’s one of many AI use cases in supply chain where tech adds measurable value.

A Broader View

From auto manufacturers using AI to schedule just-in-time parts delivery, to fashion brands using generative AI in supply chain for demand prediction across regions, examples of AI in supply chain span industries and continents.

So, how is AI being used in supply chain settings today? Simple – it’s optimizing forecasts, reducing waste, improving delivery times, and giving companies the edge they need to keep up with rising complexity.

Challenges to AI Adoption

So, is AI the silver bullet? Not quite. Like any tech shift, the road has a few potholes.

- Data headaches and integration nightmares. AI needs clean, reliable data – and not every supply chain has it. Old systems, siloed spreadsheets, and bad habits can get in the way. Integration is the name of the game, but it’s rarely a plug-and-play process.

- People and process pushback. Let’s be honest – change is uncomfortable. Employees might fear automation, or simply not know how to work with AI tools. Training, upskilling, and change management can’t be skipped. The tech is only as good as the people using it.

- Ethical and legal hurdles. From data privacy to algorithmic bias, the use of AI in the supply chain raises tough questions. Who owns the data? Who’s accountable when AI makes a bad call? These aren’t just legal questions – they’re ethical ones.

The Future of AI in Supply Chain

Let’s fast-forward a bit. What’s coming next?

Autonomous Planning Is Here – And It Pays Off

AI is now running real-time supply chain decisions, not just recommending them.

McKinsey found that early adopters in the CPG space saw:

- +4% revenue

- -20% inventory

- -10% supply chain costs

But only 7% have leaped, meaning there’s still a significant first-mover advantage.

AI + IoT = Autonomous Supply Chains

Smart shelves that talk to inventory systems. Delivery trucks that plan their routes. The fusion of AI with IoT is making autonomous supply chains a real possibility. It’s not just cool – it’s efficient.

Sustainability as Strategy

AI can help companies track carbon impact, optimize packaging, and even reduce energy use across the supply chain. Green isn’t just nice-to-have anymore – it’s business-critical. And AI is how many firms are making it happen.

Getting Ready, One Step at a Time

Don’t try to do it all at once. The smartest companies start with a focused use case – maybe optimizing digital channels or automating inbound logistics – then scale what works. AI in supply chain planning is a long game, not a quick fix.

If you’re asking about the future of AI in the supply chain, it’s autonomous, connected, and hyper-efficient – built on data, driven by smart systems, and focused on results.

Wrapping It Up

Here’s the thing: ignoring AI now is like ignoring eCommerce in 2005. It’s not a trend. It’s the future of logistics, operations, and supply chains that actually work in 2025.

Start small. Learn fast. Build smarter.

![Modern Image Classification Models [Development Notes]](https://bintime.com/wp-content/uploads/2024/07/Image-Classification-384x240.png)

![AI Product Data Mapping [Development Notes]](https://bintime.com/wp-content/uploads/2024/07/Frame-28-890x445-1-384x240.png)